metal shearing machine hazards

Employee Amputates Finger While Feeding Metal Stock Into She. Metal shavings and oil can get caught in your sheet metal shears over time.

25 Ton With 2030 X 1 6 Mm Of Bending Capacity Of Pneumatic Press Brake Power Brakes For Sale Through Online Orders Press Brake Power Brake Tools

For the purpose of this Procedure the term shear will be used to.

. Cutting off of a body part or anything else. Determine at least one control strategy from each level of the hierarchy of controls elimination substitution engineering administrative. Clean the Tool Regularly.

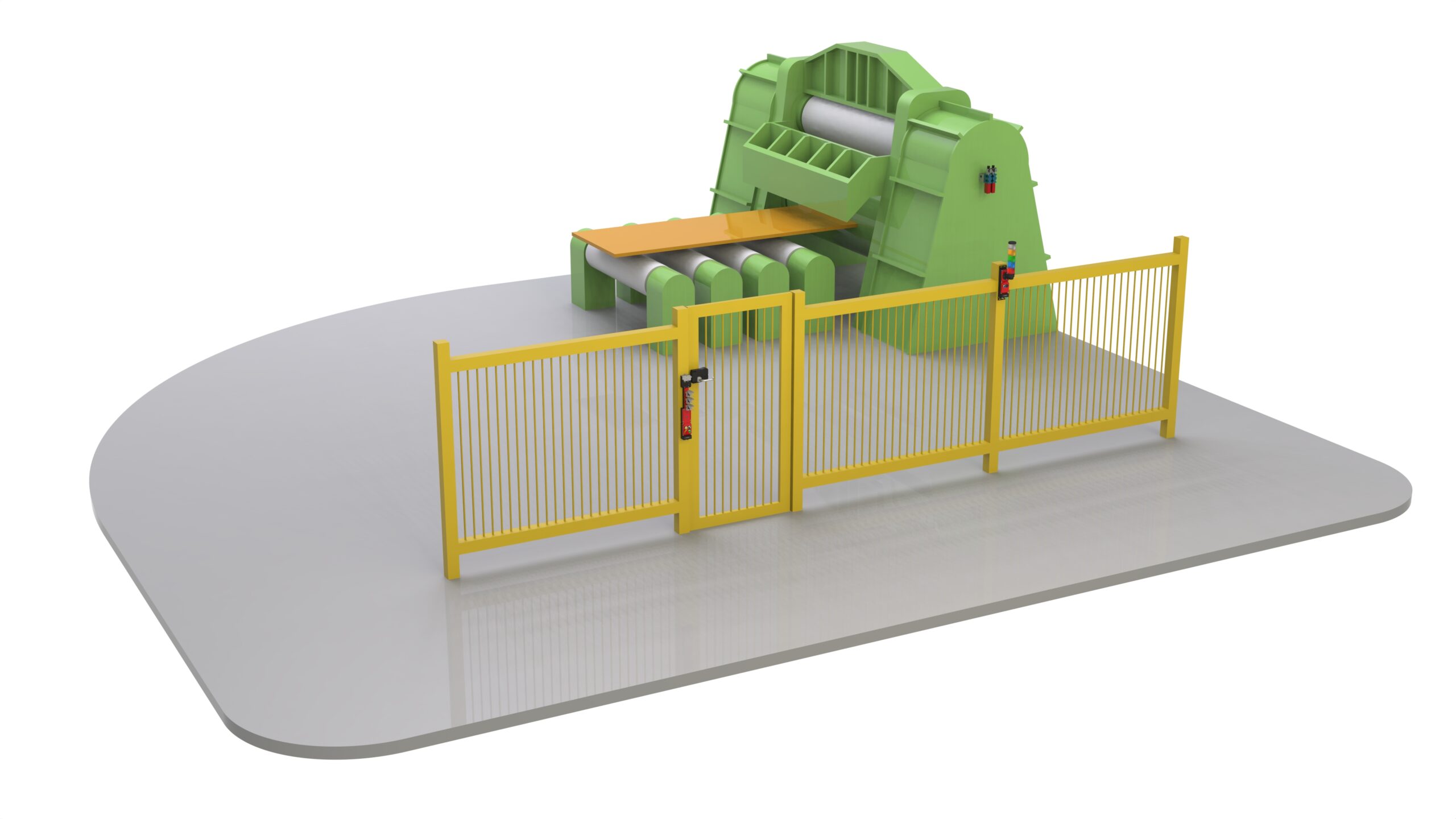

Two-Person Power Press Brake Operation with Pullbacks 26 Figure 27. Roll-Bending Machines 34 Hazards of Shearing Machines 35 Safeguarding Shearing Machines 36 Other Controls for Shearing Machines 36 Hazards of Food Slicers 37. Metal shears may be bench mounted or have integral stands and can be manually powered or electrically hydraulically andor pneumatically powered.

A heavy and deep cut on the flesh. EmployeeS Finger Is Caught In Shear Hold Down And Is Amputa. These can wear down the tools effectiveness and make it easier to get injured because sheet metal may get caught.

An endless number of hazards can occur which you should be careful of. Shearing-type operations include blanking. This will produce cut and create more sheets of various sizes and thicknesses.

Performing stressful hand activities while operating laser cutter and metal shearing machine can lead to tendon inflammation tendonitis in the hand wrist or elbow or carpal tunnel syndrome. Lifting heavy materials during the operation of a laser cutter and metal shearing machine can cause injury to muscles nerves discs and ligaments of the low back. As with any the machine has its fair share of dangers so its important to know about the proper shearing machine safety precautions.

Due to the speed of mechanical parts injury is inevitable when a body part comes in contact with a shear or cutting point. At least once a week if not after each use you should make sure the tool is free of debris. Ad Exclusive technology makes our shears easier to use and eliminates guessing.

While this guidance has not been updated to reflect current work health and safety legislation the Health and. The Hierarchy of Controls Part One. In strict technical terms the process of shearing involves the use of straight cutting bladesorm of sheet metal or plates however rods can also be sheared.

These can wear down the tools effectiveness and make it easier to get injured because sheet metal may get caught. Keeping workers safe with machine lockouts. You have been asked to identify the hazards of operating this equipment and make recommendations of ways to control the hazards.

These machines can perform a number of functions including shearing punching notching or bending. Belt Conveyor 27 Figure 28. Metal shavings and oil can get caught in your sheet metal shears over time.

These kinds of machinery require more care and precautions. Potential injuries from shear or cutting point hazards include amputation lacerations contusions crushing of tissue and broken bones. Moving parts eg risk of injuries from entanglement friction abrasion cutting severing shearing stabbing puncturing impact crushing drawing-in or.

Hazards associated with working near or on machinery vary depending on the exact machine used but can include exposure to. Employee Sustains Finger Amputation From Metal Shear. Article 108-2 of Ordinance Take measures to prevent the body parts of workers from entering the hazardous area.

Purpose Metal shears are typically used to make straight cuts in flat sheet metal stock. Shearing also known as die cutting is a process that cuts stock without the formation of chips or the use of burning or melting. Power Press Brake Bending Metal 25 Figure 26.

Stressful hand and wrist activity may be forceful repetitive or characterized by extreme postures. Needs Grading Your organization recently purchased a large metal shearing machine. Workers who operate laser cutter and metal shearing machine may face hazards from lifting and carrying manual materials handling.

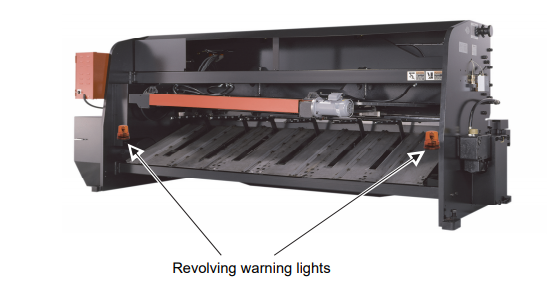

Determine at least one control strategy from each level of the hierarchy of controls elimination substitution engineering. Take necessary safety measures to prevent possible hazards caused by the shearing machineArticle 20 of Act When there is a risk that the stroke end of the machine may endanger workers take safety measures to prevent hazards. Shearing machines work with sharp cutting parts and you can bet that machines that can cut metal can easily cut through skin and bone.

Employee Attempts To Clear Jam In Shear Machine And Receives. Metal shearing machine hierarchy of controls Thursday May 12 2022 The safety guide introduces safeguarding measures that can be retrofitted to your shearing machine. At least once a week if not after each use.

Three roll bending machines.

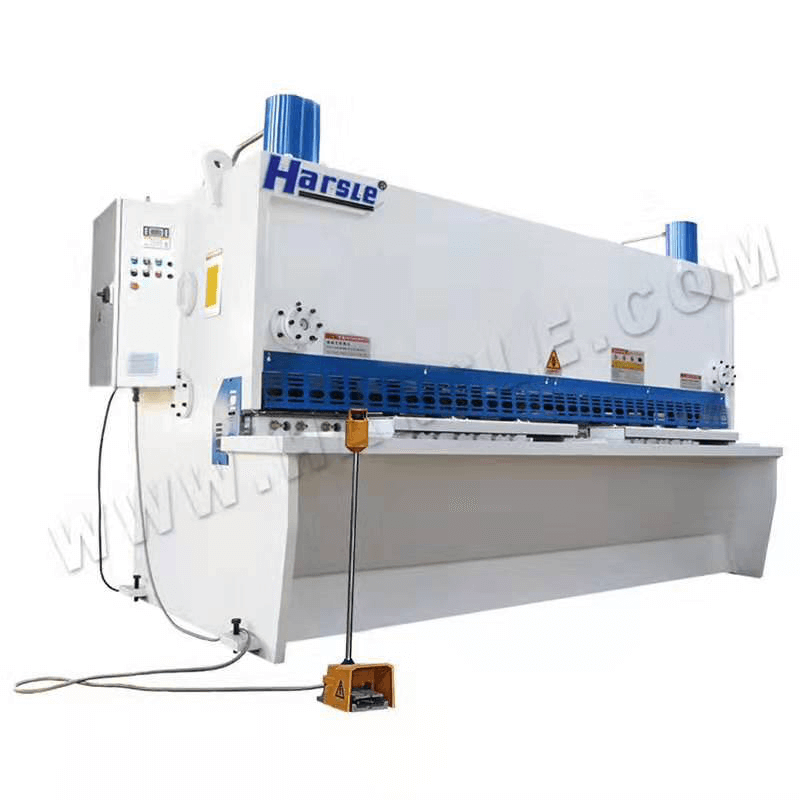

What Is Hydraulic Shearing Machine Harsle Machine

Brand New Betenbender Hydraulic Shear Sterling Machinery Hydraulic Shear Safety Switch Hydraulic

Pin On G Kendrick Power Circle Cutter Gkcc01

The Precaution Of Sheet Metal Shearing Machine Blma

Plate Shear Hydraulic Sheet Metal Working Shaeres Bending Used Machines

Safe Operation Regulations And Maintenance Of Hydraulic Shearing Machine Harsle Machine

Punch And Shear Machines Worksafe

Adjustable Hole Saw Locator Instrument Derevoobrabatyvayushie Instrumenty Samodelnye Instrumenty

Examples Of Four Primary Machine Actions

What Is Hydraulic Shearing Machine Harsle Machine

The Precaution Of Sheet Metal Shearing Machine Blma

Shearing Machine Safety Guide Harsle Machine

Metal Shearing Sheet Metal Material Removal Fortress

How To Increase The Shearing Machine Precision Harsle Machine

Pin On G Kendrick Power Circle Cutter Gkcc01

Utm 600kn Hydraulic Universal Testing Machine Hydraulic Universal Machine